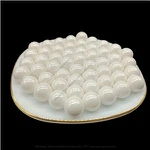

Alumina Ceramic Balls For Ball Mill

Product Color:white

Alumina content:92% 95%

Mohs hardness:9

Bulk density(g/cm3):≥3.6 3.7

Self wearing rate :≤0.15 0.1

size:dia0.5-90 mm

Certificate:ISO9001

Product Packaging: 25kg/bag / as requirement

Description

Alumina Ceramic Balls For Ball Mill are widely used in different applications due to their high strength, high hardness, high wear resistance, serious ratio, small size, high temperature resistance, corrosion resistance, no pollution and other excellent characteristics. Types of ceramics, enamels, glass, chemical and other factories in the finishing and deep processing of thick and hard materials, especially high-alumina balls with a content of 92 are the most common.

Compared with natural stone balls and ordinary porcelain balls, its wear resistance is increased by 20--40 times, the grinding efficiency is increased by 40--60%, and the grinding efficiency is increased by 30--40%, and the comprehensive cost is 40--40% of the natural stone balls. -60%, the life of the mill is increased from 2 years to 6--8 years. The wear-resistant high-alumina ceramic ball produced by our factory is selected as the grinding medium, which has considerable comprehensive benefits.

Inspection process

After the high-alumina ball is made, it needs to be inspected accordingly. The inspection steps are as follows: 1. The treated high-alumina ceramic ball is weighed with a 1g balance. 2. Then put the ceramic ball into the jar and add the same weight of water. After sealing, it needs to be sealed to prevent water leakage. Put it on the abrasion resistance testing machine and grind it at 80 revolutions per minute for 24 hours. 3. Take the alumina ball out of the grinding tank, wash it with water, dry it and weigh it. 4. The average diameter of high-alumina balls measured.

Application

1. Quartz powder:

Since its color is very white and the quartz powder is also white, it will not pollute the quartz powder during the grinding process. The hardness of quartz powder is relatively high, so alumina balls with relatively high hardness are required. The hardness of alumina balls is related to the content of alumina, and high-content alumina balls are generally used for grinding.

2. Glass

Grinding glass powder also requires high-hardness alumina balls. High-hardness alumina balls produce less impurities when grinding glass, which can improve the quality of glass.

3. Positive and negative electrodes of lithium battery

Lithium batteries have the characteristics of high voltage and high capacity. Just like chips, there can be more structures in the same space, which can increase the power of lithium batteries. At present, lithium batteries are being updated and iterated, and the raw materials are moving to the nanometer level. Both positive and negative materials have alumina balls to participate in grinding.

4. Cement powder

Grinding cement powder requires abrasives with low density, thermal conductivity and low wear. Alumina balls have this characteristic. The use of alumina balls can greatly improve the quality of cement powder.

Technical specification

|

Alumina ceramic grinding ball |

||

|

Series |

BMTL92 |

BMTL95 |

|

Al2O3 (%) |

92±0.5 |

95±0.5 |

|

Hardness(Mohs) |

9 |

9 |

|

Bulk density(g/cm3) |

≥3.6 |

≥3.7 |

|

Self wearing rate (‰) |

≤0.15 |

≤0.1 |

|

Dimension(mm) |

Φ0.5-90mm |

Φ0.5-90mm |

Product pictures

Our grind media

The production process

Hot Tags: alumina ceramic balls for ball mill, manufacturers, suppliers, factory, price, made in China, Alumina grinding media balls, Inert Alumina Ceramic Grinding Balls, Ceramic Column for Grinding, alumina ceramic media, Ceramic Grinding Ball, resistance of alumina ceramic

You Might Also Like

Send Inquiry