Inert High Alumina Ceramic Balls As Catalyst Support

Product Material: Alumina ceramic

Al2O3 : 92%

Bulk density(g/cm3) : >= 2.8 3.1 3.3-3.7

water absorption (%): <=5

Shock resistance : Good

Product Size: 3mm 6mm 8mm 10mm 13mm 19mm 25mm 50mm

Product Color: White

Certifified: ISO 9001

Customized: Availiable

Product introduction

Alumina filler balls, sometimes referred to as inert alumina ceramic balls, are substances that do not operate as catalysts and have weak chemical reactions. Since the alumina filler has a highly solid structure and a very low water absorption rate, it cannot have the same drying effects as activated alumina balls.

Feature

High alumina inert ceramic balls can withstand high pressure, high temperature, and corrosion from acids, alkalis, and other solvents. They have strong thermal stability in addition to steady chemical functionalities. Its purpose is to add a gas or liquid distribution point that can support and shield the weak active catalyst.

Production process

1. Formulate the formula according to the requirements of water absorption, aluminum content, strength, etc., and then ball mill;

Application

In sectors including petroleum, chemical, fertiliser, natural gas, and environmental protection, we frequently find inert alumina support balls. They serve as tower packings and covering support materials for catalysts in reactors in these sectors.

Technical parameters

Series | BMTL92 |

AL2O3 (%) | ≥92 |

Water absorption(%) | ≤5 |

Bulk density(g/cm3) | ≥2.8 |

Shock resistance (%) | Good |

Size(mm) | 3mm 6mm 8mm 10mm 13mm 19mm 25mm 50mm |

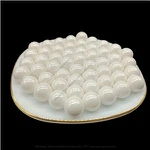

Product picture

The production process

FAQ

1:Could you produce the product as customized ?

Yes, we can do it

2:What is your packing way ?

alumina ball is 25kgs/bag, ziconia beads is 25kg/barrel , ceramic tiles is carton or upon your requirement

3:Certification

ISO

4: MOQ

500KGS or negotiate.

5:Production time

5-7 days, customized items will need 15-30days.

Hot Tags: inert high alumina ceramic balls as catalyst support, manufacturers, suppliers, factory, price, made in China, Sintered Alumina Ceramic Ball, Thermal Storage Ceramic Ball, High Purity Alumina Filler Ball, Alumina Support Balls, alumina ceramic balls, Alumina Ceramic Stuffing Balls

You Might Also Like

Send Inquiry