Zirconium Silicate Ceramic Ball

Product Code: BMRSE

Product Material: Alumina ceramic

ZrO2(%): 54

Mohs Hardness : 8

Bulk density(g/cm3) : >= 4.1

Self wearing rate : <=0.01

Size : dia1-20mm

Certifified: ISO 9001

Product Introduction

Zirconium silicate ceramic ball adopts the process of titration molding in electrolyte, high temperature baking and phasing, and there is no cavity in the bead. The medium density and hardness are suitable for grinding and dispersing medium and low viscosity slurries, which can match most sand mills and are general-purpose grinding media.

Zirconium silicate ceramic ball is made of high-purity and ultra-fine zirconium silicate powder, which has a uniform microcrystalline structure and no hollow inside. Compared with electrofusion method and other zirconium silicate beads, zirconium silicate beads have higher strength and better cost performance. Mainly used in the ultra-fine grinding of metal and non-metal minerals such as gold, silver, nickel, zinc and lead ore, heavy calcium, zirconium silicate, titanium dioxide and paints, coatings, pigments and inks.

Features

a. Due to its special process, the internal structure of the beads is uniform and dense, and the quality of the grinding material is always uniform.

b. It has good toughness, impact resistance, and the extremely small friction coefficient makes the beads wear very low to the equipment.

c. High density, significantly improving the grinding effect and efficiency

d. Low wear and long service life.

Technical specific

|

Series |

BMRSE |

|

ZrO2 (%) |

54±0.5 |

|

Hardness(Mohs) |

8 |

|

Bulk density(g/cm3) |

≥4.1 |

|

Self wearing rate (%) |

≤0.01 |

|

Dimension(mm) |

φ1-20 |

Product Application

Pigments and fuels: dispersing and grinding inorganic pigments such as titanium dioxide, carbon black and iron red; organic pigments such as peptide cyan and permanent violet;

Paints and coatings: industrial anti-corrosion paints, plastic coatings, latex paints, printing inks, inkjets, paper coatings and tapes, CD coatings, etc.;

Agriculture: pesticides, herbicides, fungicides and seed coatings, etc.;

Fillers: kaolin, titanium dioxide, mica and talc, etc.;

sandblasting;

Equipment used: vertical sand mill, horizontal sand mill, basket sand mill, ball mill, vibration mill, sand blasting machine, etc.

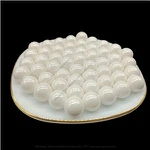

Picture

Our grinding balls

The production process

FAQ

Q : Can I place sample order?

A: Yes, OEM/ODM service is available. Customized logo/package/name/color. For details, Please kindly contact the sales persons.

A: Step1. Tell us what model and quantity you need, Get Latest Quote

Step2. Make Proforma Invoice

Step3. Confirmed PI to us, and arrange the payment.

Step4. Once we get payment, we will make production samples to confirmed

Step5. After confirmed, start to produce.

A: We accept TT.

A: The delivery time for sample order is normally 5-7 working days after prepaid payment received. For customized order, it's about 15~20

working days after deposit received.

A: For small quantity order , we ship via DHL, UPS, TNT, FedEx express. For bulk order, by air and by sea normally.

Hot Tags: zirconium silicate ceramic ball, manufacturers, suppliers, factory, price, made in China, aluminum oxide ceramic balls, Zirconia Toughened Alumina Balls, , Zirconia alumina ceramic, , alumina toughened zirconia

You Might Also Like

Send Inquiry